How the Use of Data and AI Is Transforming the Automotive Industry

These days, it’s hard to escape the chatter about partially or fully autonomous vehicles powered by artificial intelligence (AI). Skeptics and proponents alike have strong opinions on the pros, cons, and future of major innovations in the automotive industry.

Automotive companies and consumers alike stand to benefit from the transformations AI and its partner, big data, make possible. But to bring the promise of new technology to fruition, at least 15-20% of the auto manufacturing and supplier workforce will need to become tech and AI-savvy within 5-10 years—posing quite a challenge for the industry in terms of upskilling employees.

AI in Cars and the Automotive Industry

Automation has been essential to the automotive industry for decades—but there’s an important difference between standard automation tools and new AI applications. Automation in the workplace involves technology that follows a set of predetermined paths; for example, a machine programmed to perform the same task over and over on an assembly line. AI, on the other hand, analyzes data to continually adapt for greater efficiency and predict future events.

Since AI can be used to make predictions and react to changing scenarios, its potential goes far beyond what has been possible with automation alone, with applications for manufacturing, maintenance, and the driving experience. Here are five use cases of AI in the automotive industry that point to the need for upskilling employees.

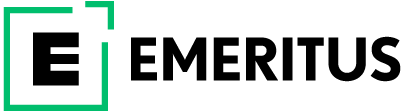

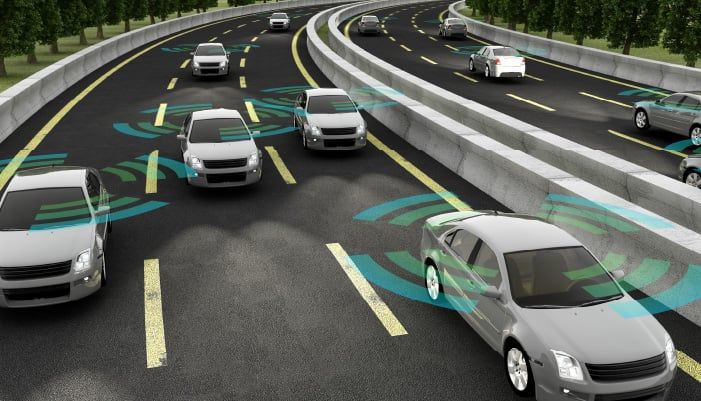

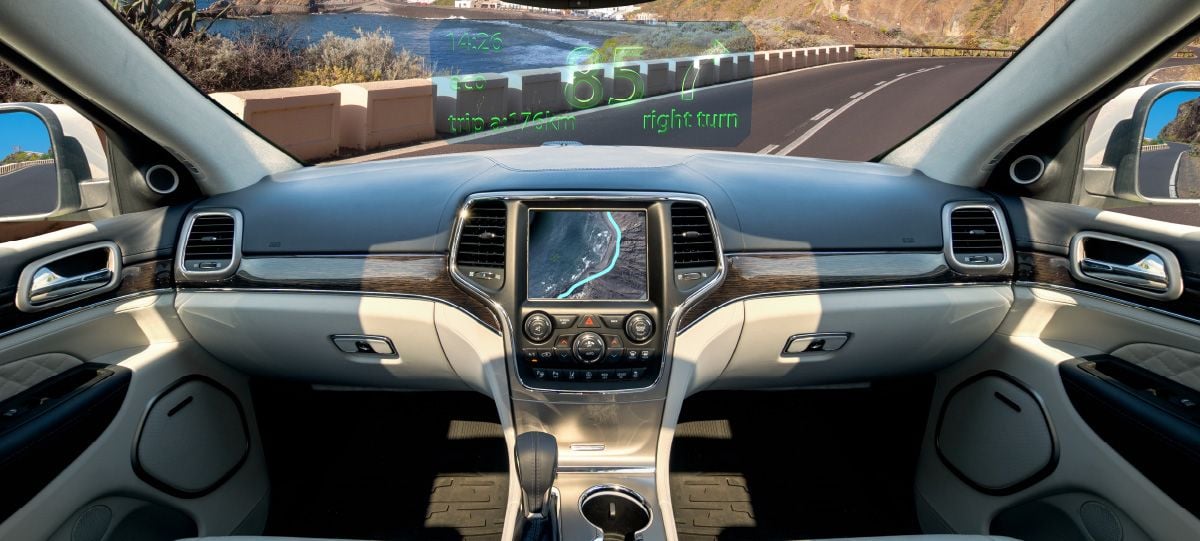

Partially and Fully Autonomous Vehicles

With testing underway by companies including Tesla, Ford, the UK’s Arrival, and Berlin-based Vay, fully autonomous vehicles will likely become a reality in the years to come.

While testing, infrastructure, and legislation mean a completely driverless future is likely decades away, lower levels of self-driving technology are already widespread. Features like lane assist, self-parking, and Tesla’s Autopilot are examples of existing autonomous vehicle technology.

Electric and Low-Emission Vehicles

AI is also helping engineers to develop the next generation of electric and low-emission vehicles. Thanks to machine learning models that can rapidly predict how batteries will respond under different conditions, engineers are iterating on fast-charging technology much more rapidly than would be possible with traditional testing methods. Further, intelligent charging infrastructures will help drivers of the future ensure they will never run out of power.

Vehicle Design and Testing

Traditional vehicle design and testing is a costly and time-consuming endeavor—especially when significant problems aren’t identified until after a physical vehicle is built. But computer modeling has typically been used to play out specific scenarios. With artificial intelligence for cars, automotive engineers can generate models that perfectly mirror every aspect of the vehicle design and test the vehicle under realistic, dynamic scenarios long before it’s built.

Manufacturing Equipment

While traditional assembly-line robots are not examples of AI, new AI applications being used on the manufacturing floor are revolutionizing how cars are produced. BMW, for example, uses AI-powered robots to build custom cars and autonomously transport materials while avoiding moving objects and people. Since these tools are powered by neural networks (a type of AI technology), they continue to learn from their environment, allowing them to adapt more quickly to challenges that arise. AI can also help prevent costly equipment breakdowns that stall production by using data from background noise, vibrations, and more to predict when machinery will need maintenance.

Quality Control

Since no manufacturing system is perfect, it’s essential to quickly identify components and cars that don’t meet brand standards. Audi uses computer vision to identify cracked parts, and Porsche uses AI during testing to identify noises that could indicate problems. AI can also identify defects up to 90% more effectively than humans, significantly reducing problems further down the road.

Big Data in the Automotive Industry

Big data has been a buzzword across numerous industries for a while now, and for good reason. The term refers to data sets that contain more variety and arrive at greater velocity and greater volumes than ever before. These data sets are too large and complex for traditional data processing methods, instead requiring advanced statistical systems and complex algorithms.

Big data in the automotive industry can include everything from data on consumer behavior and preferences to data on driving patterns, locations, and more coming in from cars on the road. Many applications of artificial intelligence rely on big data, pointing to the need for automotive engineers to understand data analytics.

Managing Supply Chain Logistics

The average passenger car has over 30,000 parts—which means there are a lot of opportunities for supply chain glitches to cause major manufacturing holdups. Using big data sets, automotive companies can perform advanced supply chain analytics that predict supply issues due to everything from local weather events to geopolitical upsets like COVID-19. With increased visibility into areas of concern, automotive manufacturers can prepare for disruptions while maintaining a lean and streamlined operation.

Recall Readiness and Management

As cars become increasingly complex, recalls are inevitable. Using big data analytics, automotive manufacturers can identify issues sooner, limiting the brand damage and financial liabilities of a recall. Additionally, big data analytics can help identify the root cause of an issue and isolate it in the supply chain to more effectively target impacted customers. Using this approach, GM was able to limit a 2013 recall to only four individual cars rather than recalling an entire model year unnecessarily.

Delivering Cars Consumers Want

Big data analytics also allow automotive manufacturers to design future vehicles to meet changing customer preferences and needs. Using data sets ranging from customer interactions to social media chatter, manufacturers can identify in-demand features and assess what price point would make them viable to the customer. Hyundai, for example, uses big data analysis for “customer-centric services or product development.” Companies can also use big data to track competitors’ products and use the insights to drive future innovations.

Creating Highly Targeted Marketing Campaigns

Big data in the automotive industry is also incredibly valuable when it comes to marketing vehicles to consumers. With data analytics, car companies can analyze their existing customers to identify characteristics that predict a purchase. Big data can also help car companies use insights like past vehicle purchases, online behavior, and demographics to create personalized marketing communications and share relevant content. They can even use it to identify strategic locations for dealerships to maximize customer retention.

The implications of these trends are clear. To stay competitive, automotive manufacturers need to be gathering and analyzing high-volume data sets and using those findings to power artificial intelligence applications. Today’s automotive engineers will need to be able to confidently use big data and AI in all aspects of their work, or risk getting left behind.

Upskilling for Big Data and AI in the Automotive Industry

Emeritus provides teams with flexible online courses in AI, data science, and analytics that are designed and delivered in partnership with leading universities. Schedule a meeting to learn how Emeritus can upskill automotive engineers in your organization for today’s workforce.

You can also explore our data analytics and artificial intelligence online programs for individual enrollment.